产品分类

Products list

联系我们

Contact us

联系人:吴经理

手机:15800518028

电话:021-69568501

邮箱:sales@shxymeter.com

地址:上海市嘉定区翔镇嘉程路1085号2幢1102室

手机:15800518028

电话:021-69568501

邮箱:sales@shxymeter.com

地址:上海市嘉定区翔镇嘉程路1085号2幢1102室

美国ADCOLE 1200-LX偏心轴综合测量机

简介:

详细说明

1.Gage Overview仪器概述

The Adcole is a high-speed, high-precision gage designed to measurecrankshafts, camshafts, pistons and other cylindrical components in demandingproduction environments.Simple to operate, with comprehensive, easy-to-understandpass/fail output reports, theModel 1200-LX is a vital tool in maintaining part quality and production process fidelityas it verifies part tolerances, minimizes scrap, flags potential quality issues, qualifies grinders and machining tools, and helpseliminate quality breaches.

Adcole1200-LX型是一款高速、高精度的测量仪, 用于在苛刻的生产环境中测量曲轴、凸轮轴、活塞和其它圆柱组件。简单的操作, 具有全面, 易于理解的是否通过要求的输出报高告,1200-LX型是保持零件质量和监控生产过成的一个重要工具, 经过它验证工件公差后,能很大限度地减少废料, 查出潜在的质量问题, 并用于磨床和加工设备的调校, 并帮助消除质量缺陷。

Adcole gages are relied on every day in major engine and engine component plantsall over the world.The Model 1200-LX gage represents over forty years of research, development and steady refinement in electromechanical-photonics technology and computer process control. The measuring gage offers exceptional performance, proven reliability, and the trusted Adcole accuracy the automotive industry has long recognized as the world standard.

世界各地的主要发动机和发动机组件工厂每天都依赖Adcole 测量仪。1200-LX 测量仪代表了四十年的研究, 发展和稳步细化机电光电子技术和计算机过程控制。该测量仪具有优异的性能、值得信赖的可靠性,Adcole 精度是汽车工业长期以来公认的世界标准。

Applications and advantages of the Model 1200-LX measuring machine include:

1200型 LX 测量机的应用和优点包括:

•In-line and end-of-line quality inspection.

•在线和线外质检.

•Saves costs in both labor and materials.

•节省劳动力和材料的成本.

•Accept new machine tools.

•适用新的工装.

•Control over manufacturing process.

•控制制造过程.

•Verifies grinders, milling machines, polishers and other machine tools.

•验证磨床、铣床、抛光机和其他机床.

•Minimizes scrap and rework to maximize good part production.

•少的废品和返工,从而得到很多的合格品

•Proof of part quality and production expertise.

•验证部件质量和生产技术.

•Correlates with other Adcole gages at machine suppliers, prototype and design facilities and other manufacturing locations.

•与其他Adcole 测量仪在机床供应商、原型和设计设备以及其他制造地点的关联.

•Make fast and efficient measurements of first-off parts after wheel changes and part changeovers.

•进行快速有效的首件检验或换工件加工或砂轮后的检验。

Design advantages of the new Model 1200-LX:

新机型 1200-LX 的设计优势:

•New, modern cabinet houses all components:main gage, electronics, peripherals and tooling drawers. The innovative design takes up considerably less floor space, ships on one skid, and installs with factory wiring.

•新的、现代化的橱柜内容纳了有所有组件: 主量具、电子设备、外设和工装抽屉。创新设计占用相当少的地板空间,一个箱子发运,并可接工厂线

•Accuracy has been improved with lower spindle runout less than 125nanometers (nm) and radial measuring resolution of 5 nm.

•精度已得到改善, 较低的主轴跳动小于125纳米 (nm) 和径向测量分辨率为 5 nm.

•Enclosed measuring chamber with interlocking, easy-swing door improves operator safety, eliminates the need for air pressure system and keeps the gage clean.

•封闭测量空间, 带锁、易开关的门, 提高了操作者的安全, 消除了气压系统的需要, 使量具保持清洁.

•New LED task lighting enhances part visibility and doubles as GO/NO-GO indicator by changing color.

•新的 LED 任务照明增强了部件的可视性, 并通过更改颜色来显示 "go/无 go" 指示器.

•Brushless DC servo motors with encoder feedbackfor carriage and headstock drives improve gage speed, performance, reliability and accuracy.

• 无刷直流伺服电机与编码器的反馈, 为滑架和头座驱动器提高了测量速度, 性能, 可靠性和准确性.

•Linear motors reduce follower friction and increase accuracy.

•直线电机减少测头摩擦和提高精度.

•New user-friendly software makes part sequence writing, report generation, and SPC files quick and easy to produce.

•新的 人机友好界面使部件序列编写、报告生成和 SPC 文件快速且易于生成.

•The roof of the gage has been designed to accommodate an optional load assist device for heavy parts. By mounting the assist device on the roof, part loading is easier and requires less floor space.

•量具的顶部设计为适用于重型零件的可选负载辅助装置。通过安装在屋顶上的辅助装置, 部分装货更容易,需要更少的地板空间

2.Technology技术

The gage is constructed from granite and steel and sits on vibration dampening air mounts. Workpieces are loaded vertically into the machine and clamped between a headstock and a tailstock. The tailstock (a) is vertically adjustable to accommodate various shaft lengths.

该量具是由花岗岩和钢建造, 底部布置有气垫。工件垂直装入机器, 夹在主轴箱和尾座之间。尾座 (a) 可垂直调节以容纳不同的轴长度。

A carriage (b) containing the radial measurement system, aka, follower (c) sits alongside the workpiece. The follower engages the workpiece, which is then rotated or scanned linearly depending on the desired measurement.

包含径向测量系统的运输 (b), 又名, 测头 (c) 坐在工件旁边。测头啮合工件, 然后根据所需的测量线性地进行旋转或扫描。

The size and shape (straight, round, knife edge, etc.) of the follower can be varied depending on the measurement task. All Adcole followers are cryogenically hardened for maximum durability and to eliminate measurement errors that can occur with easily worn-down followers.

测头的尺寸和形状 (直、圆、刀边等) 可以根据测量任务的不同而变化。所有 Adcole 的测头都低温硬化, 以很大限度的耐用性, 并消除可能因使用不耐磨的测头所发生的测量错误。

2.1Gage Characteristics仪器特征

The smallest1200-LX gage line comes in 0.7M s.

1200-LX型尺寸 (0.7M)。

Specifications规格:

•Part Length Capacity: 0.7 Meters

•零件长度: 高达1米或高达1.5 米的

•Swing Diameter: 302 mm (11.88")

•回转直径: 302 毫米 (11.88 ")

•Part Weight: 341 kg (750 lb.)

•工件重量: 341千克 (750 磅)

•Follower Stroke: 190 mm (7.5") maximum

•测头冲程: 190 毫米 (7.5 ") 很大值

•Follower Speed: 25 mm/s (extend) & 125 mm/s (retract and fast extend)

•测头速度 25毫米/秒 (延伸方向) & 125 毫米/秒 (退出和快速延伸)

•Follower: 2.3 mm (0.09”) radius, carbide

•测头: 2.3 mm (0.09 ") 半径, 硬质合金

•Traverse Speed: 2286 mm (90") per minute (vertically)

•滑架速度: 每分钟2286毫米 (90 ") (垂直方向)

•Rotation Speed: 1 to 30 rpm

•旋转速度: 1到 30 转每分钟

•Paint color: ADCOLE Grey (RAL 7035)

•油漆颜色: ADCOLE 灰色 (RAL 7035)

•Power: 220 VAC, 50/60 Hz single phase

•电源: 220V交流, 50/60 赫兹单相

•Size - Gage: 1916 mm W x 1720 mm D x 2535 mm H

•尺寸-量具: 1916毫米 宽 x 1720毫米深 x 2535 毫米 高

•Weight: 2495 kg (5,500 lb.) approximate

•重量: 2495千克 (5500 磅) 近似

Gage Accuracy:

仪器精度

•Radial: < 0.4 μm

•径向: < 0.4 微米

•Diametric: =/-0.5 μm

•直径: =/- 0.5 微米

•Angular: < 1 arc second with angle correction

•角向: < 1 角秒内通过角度补偿

•Spindle: less than 0.125μm TIR

•主轴: 低于0.125 微米跳动

•Linear Straightness: less than 0.4 μm over 100 mm

•线性直线度: 100毫米以上低于0.4微米

•Overall Error: less than 10% of typical industry part tolerance

•总体误差: 低于典型工件公差10%内

Gaging Time - 4-cylinder gasoline crankshaft (5 main, 4 pin journals):

测量时间-4 缸汽油机曲轴 (5主轴颈, 4 连杆颈):

Complete using three radial cuts (traces/scans) and one vertical trace for straightness on each main journaland pin journal: 4.5 minutes. For longer, diesel crankshafts the cycle-time will be longer, approximately 7minutes without printing time (as these may vary). Pin Journal length measurements (cheek widths todatum) will add an estimated 1 minute. Part load and unload estimated at a maximum of 0.75 to 1 minute.

在每个主轴颈及连杆颈上完成三个径向截面测量和一个垂直方向的直线度扫描: 4.5 分钟。对于更长的柴油机曲轴的周期时间将会更长, 大约7分钟不包含打印时间 (因为这些可能会有所不同)。连杆颈长度测量增加估计1分钟。零件上料和下料的估计很大值为0.75 到1分钟。

2.2Measured Parameters

测量的参数

The machine measures cylindrical, concentric, and eccentric features and/or eccentric lobes on crankshafts, camshafts and many other types of cylindrical parts

该设备可测量圆柱度、同心度和偏心特性和/或偏心凸轮在曲轴、凸轮轴及许多其他类型的圆柱形零件。

2.2.1Crankshaft Measuring Program

曲轴测量程序

The Adcole crankshaft measuring program provides the capability to evaluate a variety of crankshaft parameters including:

Adcole 曲轴测量程序提供了评估各种曲轴参数的能力, 包括:

•Main and pin journal diameter, measured at three locations per journal (over oil holes where required). Accommodates journals of different diameters within the same part.

•主轴颈和连杆颈的直径, 测量三个位置 (需要时可穿过油孔)。适应于同一工件的不同直径.

•Main and pin journal circularity (roundness) with LSC, MZC (MRS), MIC and MCC circle evaluation methods according to ISO 6318. Evaluates lobing and chatter over 360 degrees and in selectable sliding window.

•根据 ISO 6318 的标准, 用 MZC (MRS)、MIC 和 MCC 圆评价的方法, 对主、连杆径圆度进行分析。在360度里评估区域圆度和振纹, 并可在滑动窗口选择.

•Main and pin journal cylindricity

•主轴颈及连杆颈圆柱度

•Main and pin journal straightness (linear profile)

•主轴颈及连杆颈直线度(线性轮廓)

•Main and pin journal taper

•主轴颈及连杆颈锥度

•Main journal parallelism

•主轴颈平行度

•Main and pin journal center deviation

•主轴颈和连杆颈中截面误差

•Main and pin journal width, lengths and their position with respect to the thrustface

•主轴颈及连杆颈宽度,长度,及其对于止推面的位置

•Main journal and all diameters centerline runouts relative to No’s 1and 5 and also to centers

•主轴颈及所有直径中心线关于1,5及其他轴颈中心的跳动

•Main journal concentricity / eccentricity and part bow correction to end journals

•主轴颈同心度/偏心度及对于工件两端的弯曲补偿

•Pin journal angular position (index error)

•连杆颈角度位置(分度误差)

•Pin journal throw and true position

•连杆颈冲程及位置度

•Pin journal parallelism to mains axes in two (2) planes

•连杆颈平行度对于两个测量面的轴心

•Thrustface runout of main journals to end journal reference (1 and 5) and squareness

•主轴颈对两端轴颈(1,5)的止推面跳动及平面度

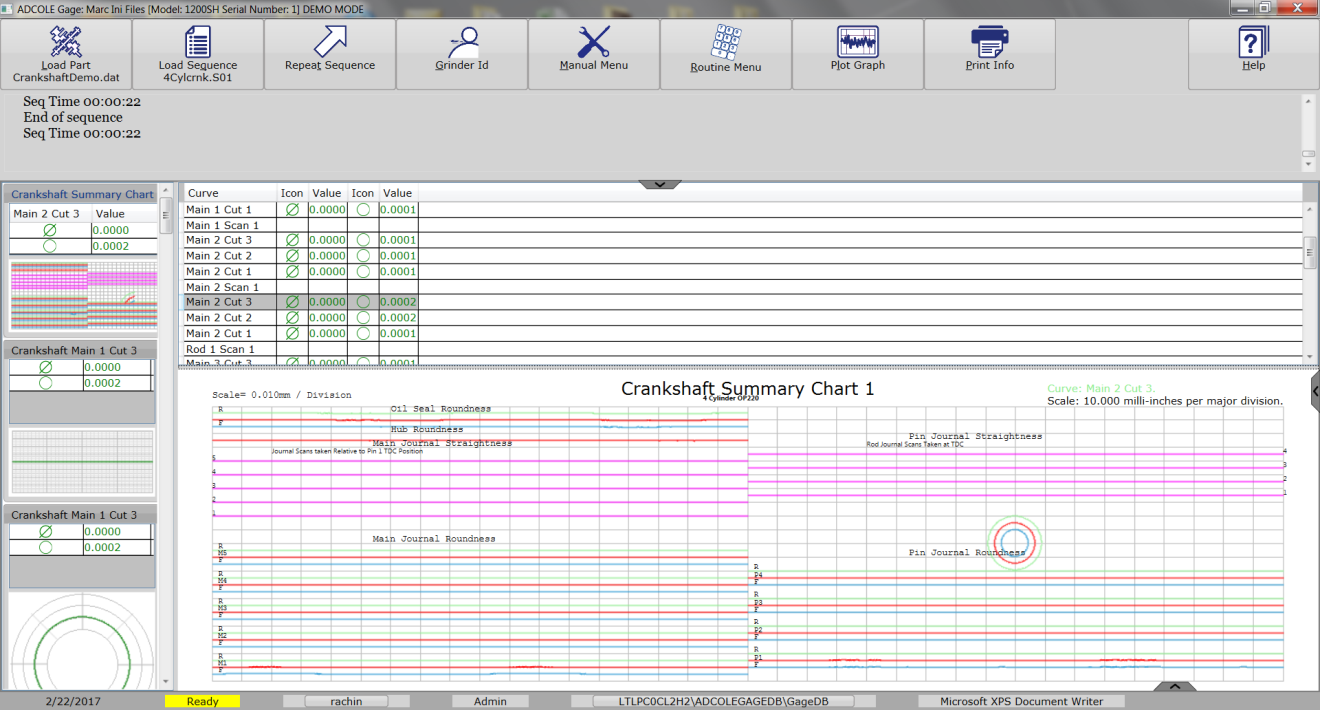

•Straight line error plots or polar plots to display or printer with reference circle

•在屏幕或绘图机上显示或绘制相对圆的直线误差图或极坐标误差图

2.2.2Camshaft Measuring Program (Optional)

凸轮轴的测量程序(选项)

The Adcole camshaft measuring program provides the capability to evaluate a variety of camshaft parameters including:

ADCOLE凸轮轴测量程序可以提供测量和评价下开各种凸轮轴参数的功能

•Cam journal diameters and circularity (roundness)

•凸轮支承轴颈的直径/周向突变量

•Cam journal run-out

•凸轮支承轴颈的跳动

•Cam journal eccentricity to gage axis and part centers, and adjacent journals.

•凸轮支承轴颈的相对仪器的轴线及工件中心及相邻轴颈的偏心度

•Cam journal cylindricity, parallelism, taper and straightness

•凸轮支承轴颈的圆柱度,平行度,锥度和直线度

•Cam lobe #1 angle to various timing references (timing holes, timing pins, keyways).

•1号凸轮角度对于不同角度基准(相位孔,相位销,键槽)

•Cam lobe angle error: of all cams to timing reference and of all cams in relation to each other

•凸轮角度误差:所有凸轮对于相位基准及相互角度

•Cam lobe base circle radial error, runout, and velocity error

•凸轮基圆半径误差,跳动和速率误差

•Cam lobe maximum nose lift error (relative to base circle) and location where maximum error occurred

•凸轮桃尖段的很大升程误差和产生很大误差的位

•Cam lobe maximum ramp lift error (relative to base circle) and location where maximum error occurred

•凸轮过度段的很大升程误差和产生很大误差的位置

•Cam lobe nose lift velocity error and location where maximum error occurred

•凸轮桃尖段的很大速率误差和产生很大误差的位置

•Cam lobe ramp lift velocity error and location where maximum error occurred

•凸轮过度段的很大速率误差和产生很大误差的位置

•Cam lobe taper, center deviation, parallelism and straightness

•凸轮锥度,中截面偏差,平行度和直线度

•LSC, MZC (MRS), MIC and MCC circle evaluation methods according to ISO 6318

•二乘圆(LSC),很大内接圆(MIC),小区域圆(MCC)的计算符合ISO 6318标准。

Filters are Gaussian digital with optional 2CR.

过滤器是高斯数字与可选2CR。

Waviness filters in accordance with current ISO standards with 1:15 / 1:50 / 1:150 upr freely selectable. All programs will initially be supplied with 1:50 upr.

波纹过滤器与当前 ISO 标准符合与 1:15/1:50/1:150波动/转可自由地选择。所有项目初将提供1:50波动每转。

Note: Where applicable, form and location parameters are measured in accordance with the definitions contained within the International Standard, ISO 1101.

注意: 如果适用, 表格和位置参数按照国际标准 ISO 1101 中所包含的定义进行测量.

2.2.3Output Reports

输出报告

Various profile and error graphic plots:

各种轮廓和误差图形绘制

•Journal roundness, linear or polar

•轴颈圆度的线性图和极坐标图

•Journal straightness, linear

•轴颈直线度线性图

•Numerical Summary Report

•数字汇总报告

2.3Gage Design Features

仪器设计特征

•Robust machine base with pneumatic isolator mounts

•带气动吸震器的坚固机器底座

•Heavy duty, ball bearing spindle headstock

•重载荷精密滚珠轴承主轴头架(转台)

•Heavy duty precision tailstock with carbide center

•重载荷精密硬质合金顶尖

•Precision granite base plate, flat to 0.00127 mm/305 mm, with full length lapped vee-way

•精密花岗岩立柱导轨,平面度达1.27微米/305毫米,V型导轨是经研磨加工

•Precision ground carriage-way and radial measuring slide

•精密磨削的滑板导轨和径向测量滑板导轨

•Adjustable precision tailstock assembly with 60 mm travel and carbide tip center

•38毫米可调行程的精密硬质合金尾架

•Carbide follower, 0.180” diameter, straight to 0.001 mm or radius type followers

•硬质合金测量圆柱,4.57 mm直径,直线度1 um或半径类型测头。

•Machine cover / machine labeling in English (Optional Second Language)

•机床罩/机床英文标签(第二语言可选)

•Side Acting Sensor for Lateral/Spacing Dimension checking

•侧向移动传感器,对两侧/间距距离检测

Accurate crankshaft measurement demands a gage with high precision, as the rod journals are eccentric to the part axis, requiring a long accurate motion of the follower. One arc second of angle error can result in a radius measurement error of 0.12 microns per 25 mm.

精确的曲轴测量要求高精度的量具, 因为连杆颈是偏心于零件轴线, 要求一个耐用并且准确的测头。1角秒角度误差可以导致半径测量每25mm有0.12微米误差.

For a crankshaft with a 50 mm throw, a one arc second error in angle can result in a radial error of 0.24 microns on a pin journal. This is 4.6% of the roundness tolerance for a typical high precision crankshaft.

对一个50毫米偏心距的曲轴,一秒弧度的角度误差可以在连杆颈径向方向上产生0.24微米的误差。该误差约为典型高精度曲轴圆度公差的4.6%。

The Adcole Model 1200-LX gage is based on a high precision ball bearing spindle, precision carriage and unique follower design.Since the runout of the spindle directly affects accuracy, a steel ball bearing spindle--designed and manufactured by Adcole-- is used in all Adcole gages. The robust spindle was designed for maximum accuracy and extended service with a runout of less than 0.01 µm and an angle accuracy of less than one-half arc second (calibrated).

Adcole 型号 1200-LX 测量仪具是基于高精度滚珠轴承主轴, 精密滑架和独特的测头设计。由于主轴的跳动直接影响精度, ADCOLE使用了自行设计制造的钢球轴承主轴。这种坚固的主轴能在载荷下达到跳动小于0.01μm及角度精度低于半个角秒(标定后)

The Adcole follower employs a stiff steel carriageway and custom made, low-runout bearings that minimize follower deflection. Any resulting pitch and yaw motion effected as the follower extends/retracts is measured by the three laser tracks of the laser interferometer system and used to compensate final measured results. The long measurement range of the follower provides access past the gage axis.

ADCOLE采用坚固的滑道和球轴承导轨,使测量头的偏差减少到小。测量头在伸缩测量运动中产生的偏摆等误差由三个激光测位器监测并在测量结果中作补偿。测量头的较长行程可使测量头超过转台的轴线。

Laser Interferometer:

激光干涉系统:

To achieve the maximum accuracy, an Adcole designed laser interferometer is used to determine the carriage and follower (radius) position to 0.005 micron resolution. The proven Adcole design utilizes three laser paths for dynamic correction of any pitch and yaw errors. Radial measurements are accomplished with reference to a mirror, flat to within 0.125 microns. This design provides the sub-micron accuracy required for journal straightness, parallelism and roundness measurements.

为了获得高精度,采用ADCOLE设计的激光干涉仪来确定滑板和测量头(径向测量)位置,其精度可达0.005微米。已被认证的三路激光束作为任何偏摆误差的动态修正。径向测量以一平镜作为基正,平面度小于0.125微米。这种设计提供了测量轴颈直线度,平行度和圆度所需的亚微米级精度。

Dynamic calibration is achieved (since the gage axis is accurately determined by the laser interferometer) using the mirror as a reference. Thus, the measurement of a master shaft is not required to accommodate a change in part length. This saves you time and the large expense of certifying and maintaining mastershafts.

实现了动态的校准,因为仪器轴向是由激光干涉仪通过基准镜子精密测定的。这样就不需要有和工件一样长度的标准芯轴来校准仪器。这能够节省你的时间和大量校准的费用。

Electronics:

电器系统:

•Touchscreen monitor, keyboard, and mouse mounted on pivoting panel for operator ease-of-use and sound ergonomics.

•触摸显示器,键盘,固定在可翻开面板的鼠标为便捷使用及符合人体工程学

•Standard computer, min. 250 GB hard drive, 4 GB RAM, DVD-RW drive. (Used to process measured data and provide the operator interface for programming and controlling the gage)

•标准计算器,低250G硬盘,4GB内存,DVD-RW驱动。(通常处理测量数据及提供编程及控制的操作界面)

•HP Deskjet A4 colour graphics printer (or equivalent device)

•HP 喷墨打印机 A4 彩色绘图(或同等设备)

•Computer with sliding shelf for keyboard/mouse and TFT 19” touch screen monitor housed in a ruggedized, sealed industrial cabinet for shop-floor use.

•电脑带有可移动式架子用于键盘/鼠标及19英寸触摸显示器放置,密封工业柜专用于车间。

2.4Gage Software and Operation:

仪器软件及操作

The gage software program accommodates an unlimited amount of part numbers and separate gage operations for each part number.

仪器软件编程可将不同零件的文件和测量程序不受限制地存储。

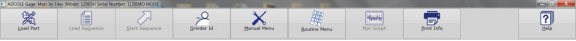

Operation of the gage is accomplished via user friendly Touch Screen software program. The Main Menubuttons are shown below:

操作者可以通过装备了Adcole友好操作软件的触摸屏进行操作,主菜单显示如下

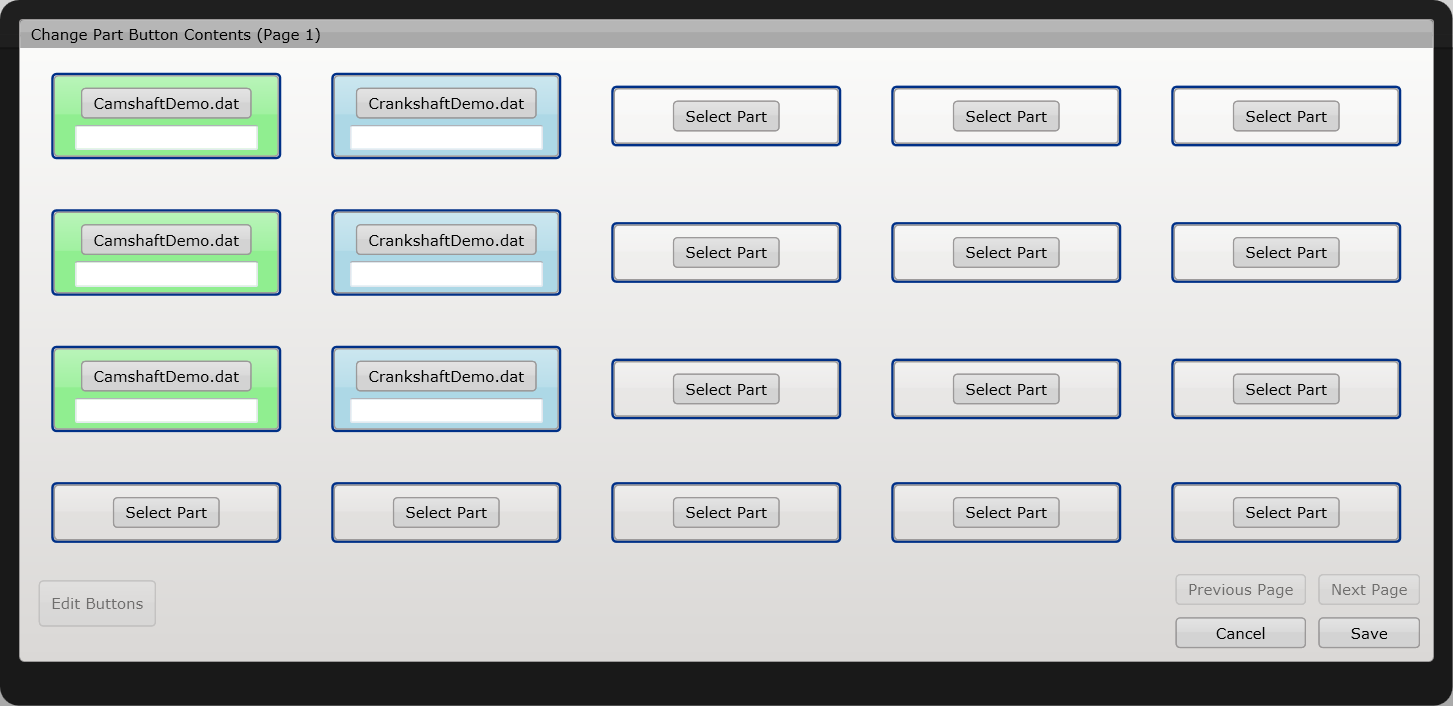

An operator simply tapsthe LOAD PART key on the touch screen and is immediately shown the gages full inventory of programmed parts.

操作者可以简单的点击在屏幕上的上料按键,将立即显示出已经编辑过测量程序的工件

The operator selects the desired part from the options list and is then returned to the main screen to begin measurements.

操作者从列表中选择想要测量的工件,即回到主界面开始测量

Data appears on the screen in real-time, charting and recording the measurements as they progress. Upon conclusion of the measurements, an output report is displayed which can be printed or stored by the operator.

数据将在屏幕中实时,以图形方式出现,并记录它们的测量进程。根据测量结果,输出报告可以由操作者打印或存储于电脑中

2.5Gage Programming

仪器编程

The Model 1200-LX is easily programmed with output driven instructions. Creating new part files, measuring sequences, output and SPC reports can be accomplished in just a few clicks and with minimal data input.

1200型测量仪很容易在没有指导的情况下完成编程,创建一个新的工件文件,测量指令,输出及SPC报告能在很少点击及数据输入下实现。

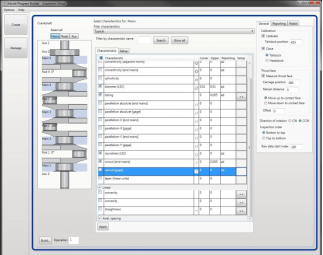

Inspection Program Menu:

检测程序菜单:

3.Optional Software Packages:

可选软件包

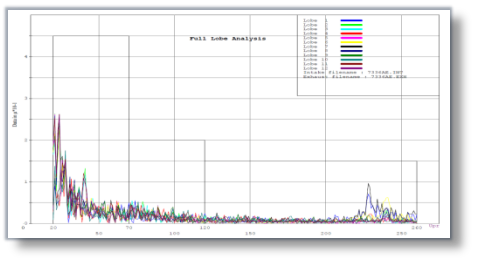

3.1Chatter Analysis Software (for Camshafts and/or Crankshafts)

振纹分析软件(对于凸轮轴/或曲轴)

This specially developed software determines and reports maximum amplitudes for customer-assigned frequencies and lobe regions. FFT analysis can reveal otherwise unobservable periodic signals by transforming the error data into a set of harmonics in the frequency domain. Outputs are in color-coded bar graph format, frequency verses amplitude. Out of tolerance amplitudes are reported numerically as well as graphically.

这个专门开发的软件确定并报告客户分配的频率和叶区的很大振幅。FFT 分析可以通过将误差数据转换成一组频域中的谐波来揭示观测周期信号。输出是彩色条形图格式,及振幅频率。输出的振幅及公差带将以数字及图形化报告。